The DC-DC Conversion Module is a common power converter, which can realize the conversion of high/low Direct Current. After conversion, it can realize a single output or multi-channel output of different specifications. Widely used in electric automobile, aviation, military industry, industrial automation, LED lighting, communications, information and medical industries, etc.

The functional verification of the DC-DC Conversion Module is very crucial, as for the traditional handcraft testing, has been unable to meet the growing market demand, no matter in efficiency or accuracy. The advantages of the automatic test system gradually replacing the traditional handcraft testing become more and more obvious, and it can also bring huge benefits to companies:

1) Reduce manpower expense

After the implementation of the automatic test system, it reduced the test engineers' manpower and time investment;

2) Improve efficiency

All the items to be tested can be carried out automatically and a test report can be generated, without changing the line connection manually in the process, which is far more efficient than the handcraft testing method;

3) Reduce the error rates

Due to the increase in workload and duration, the testers are fatigued, inertial thinking or thinking slackness, however, the machine can ensure the quality of non-stop running, and meet the test requirements when additional tasks are added as well;

The general working process of this system is introduced and shown below; we take the needs of a domestic end user as an example.

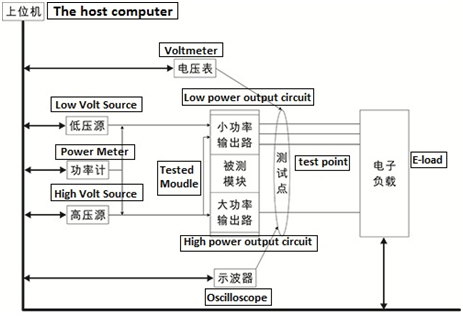

The host computer, provides an operation interface, for controlling the test actions of each instrument in this system, and can also determine the test results;

Low voltage source/high voltage source, provides DC voltage input that meets the specifications, and can also be used to provide external voltage injection during the overvoltage protection testing;

The Power Meter, measures the parameters of the input terminal, including voltage, current, power, etc., matching up to the measured value of the output terminal, can also obtain the efficiency value of the object to be measured;

Voltmeter can be used to measure voltage, current (with shunt), resistance and other parameters; Oscilloscope can be used to measure the waveform of the voltage rise/fall time of the object under testing;

System Diagram:

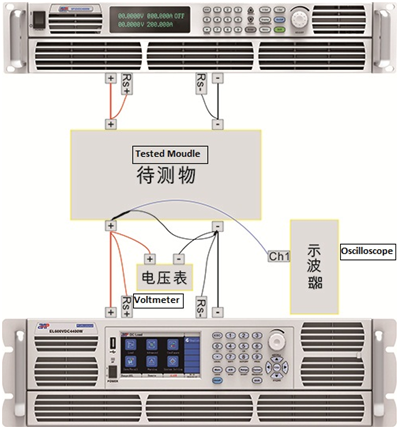

Testing Wiring Diagram:

Software control interface:

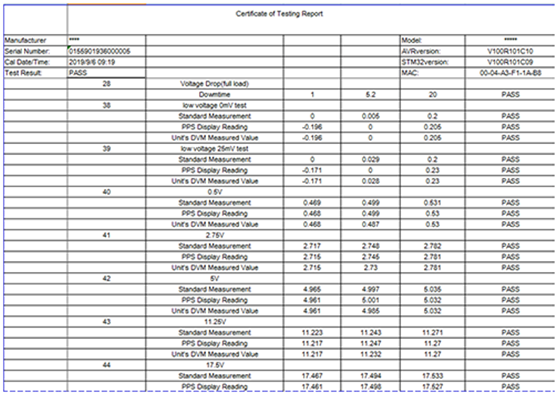

Test Report Output:

AT-T2000, as the new generation Automatic Test system of APM Technologies, its features are as below:

1. Optimize standard test items for various power supply products, easy to learn;

2. Open hardware platform, can increase or decrease test equipments according to customer needs;

3. Open software platform, modular design, which can be used by users to expand test items;

4. Multi-account management with separate authority to avoid unauthorized modification;

5. Barcode scanning automatic retrieval program, also supports single or multi-channel online testing simultaneously;

6. When judging conditions are added, a graphical reference interface can be automatically popped up to prompt the operator to handle;

7. The test report is automatically uploaded to the shipping system for easy traceability;

This series of systems can realize including but not limited to the following test contents:

1. Input power test;

2. Input peak current test;

3. Input Undervoltage test;

4. Input and output timing test;

5. Voltage/current accuracy test;

6. Voltage/current load regulation test;

7. Start overshoot test;

8. Efficiency test;

9. Ripple test;

10. Output short circuit test;

11. Overcurrent protection test;

12. Overpower protection test;

13. Voltage rise/fall time test;

14. On/off time test;

15. I/O signal monitoring;

16. Communication detection;

Based on more than 10 years of experience in automation system integration, APM Technologies continues to provide solutions for customers in different fields. We provide various of Products, including Programmable Ac Power Sources, Dc Power Source, Dc Electronic Load. Do not forget the original intention, and keep the mission of APM in mind, to minimize the work load of people, increase life convenience, and save more human resources.