The company is headquartered in France and the order is from Brazil office. The application is for vehicle motor test. Customers spent months testing the product's performance, stability and reaction speed, and finally firmly chose APM technologies programmable DC power supply.

Test subjects(Part)

Customer test scene (Part)

The testing process includes the following equipment:

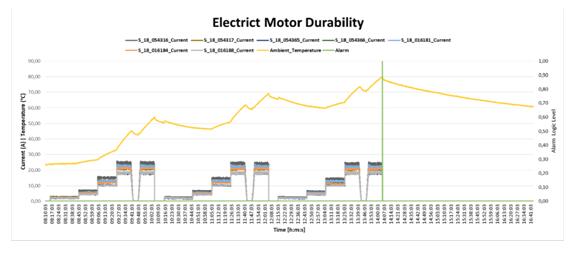

The motor to be tested is placed in a constant temperature and humidity box whose temperature varies from -40 ℃ to 70 ℃. The data acquisition system is responsible for collecting and storing the current of the motor and displaying the temperature of the constant temperature and humidity box on the computer interface synchronously. This is a test project that may last for months. If the motor is abnormal, the current exceeds the set limit, or the constant temperature and humidity box is abnormal, and the temperature exceeds the set limit, the data acquisition system will immediately send a signal to the power supply (high level signal), and after receiving the signal, the power supply will immediately shut down to protect the object to be tested.

During this unattended test, the temperature of the constant temperature and humidity box is happened to be abnormal, which causes the temperature in the box to rise sharply (yellow curve in below figure). The data acquisition system detects the abnormal and sends a signal to the power supply, the power supply immediately turn off the output (green line in below figure), which protects the customer's objects and equipment to be measured and avoids potential losses and risks. After the test, the customer sent a thank-you email and confirmed to choose APM technologies programmable DC power supply with satisfaction.